Adam Schade's Design Portfolio

I’m a mechanical engineering student passionate about turning ideas into tangible solutions through creative design and advanced engineering tools. With expertise in CAD modeling, FEA simulation, and rapid prototyping, I thrive on developing innovative products that balance functionality and user experience. My background includes hands-on work with 3D printing, robotic systems, and collaborative design projects, complemented by Lean principles to ensure efficiency and continuous improvement. I approach every challenge with curiosity, precision, and a drive to push boundaries in engineering design.

Here is WHAT

I can DO

Prototyping

Every design needs to start somewhere, whether it's for a space probe or a toothbrush. I have extensive experience with all areas of prototyping, including design research, idea generation, iterative design, and implementation of stakeholder feedback.

3D Design

If you can think it, I can make it! As a certified SolidWorks professional with over a decade of CAD experience, I have the ability to turn any idea into a full 3D model.

Multidisciplinary

My skillset extends beyond my technical engineering background. From programming to project management to video editing, I have the flexibility to tackle whatever requirement a project needs. I also have communication skills atypical of most engineers in that I can communicate technical concepts to people of any background.

Leadership

Every team needs a leader, and I have plenty of leadership experience under my belt. I am the cohesive aspect of any group and I ensure every team member can reach their fullest potential while ensuring the project stays on time and under budget.

Here is WHAT

I have DONE

AI-Powered Recycling Sorter

As part of my University's Capstone Design program, our team was tasked with assisting a recycling company in creating a device capable of sorting compostable plastics from other general refuse. Our design utilized AI and machine learning algorithms to recognize and sort recycling with a high level of accuracy. Our design won awards for "Best of Award for Environmental Impact" and "Most Inspiring for Future Engineers Award".

Lean/Six Sigma Green Belt

During my lean engineering co-op at Entegris Inc, I had the opportunity to lead a lean/six sigma green belt project to redesign the layout and product flow of a plastic injection molding workcell. The project followed a DMAIC format (define, measure, analyze, improve, control), and required the use of different lean/6S tools. Microsoft Project was used to manage progress and track milestones. I collaborated with multiple departments to finalize a design that maximized spaced efficiency and operator utilization. The project is still ongoing, and is expected to finish with my Green Belt certification in early 2026

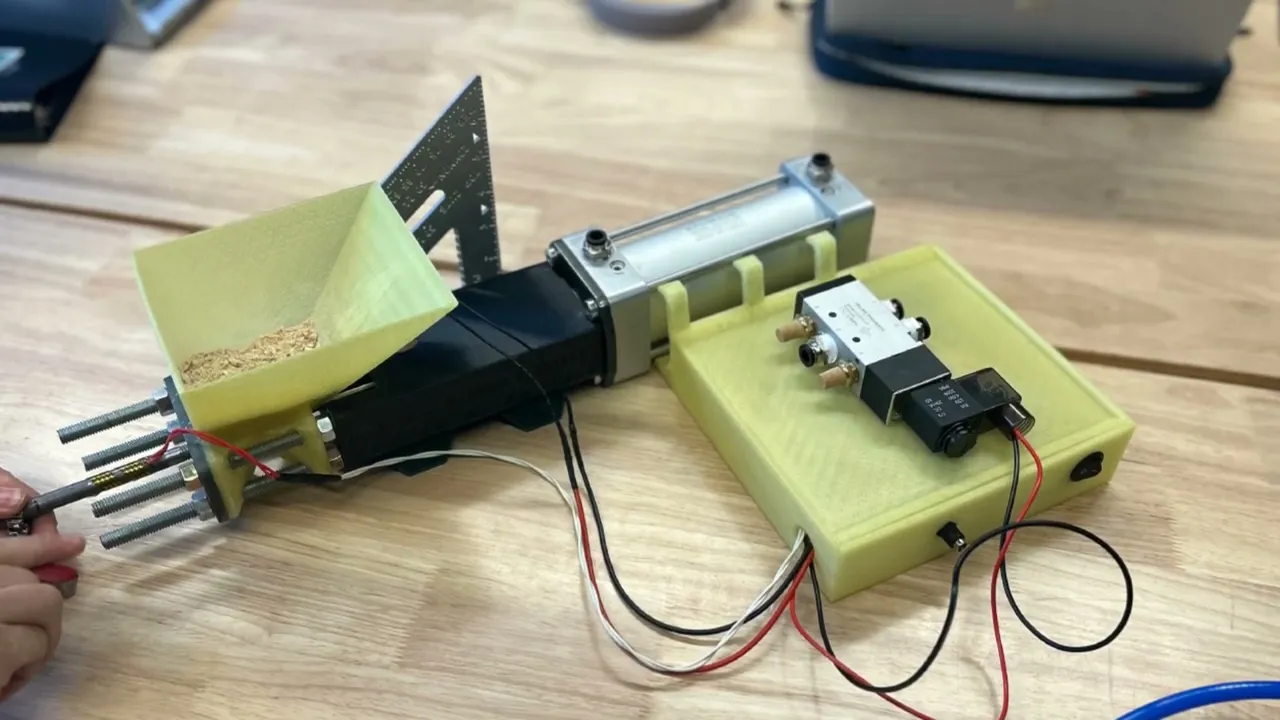

Briquette Maker

I worked with a team of 6 to design and prototype a robotic device that creates solid burnable briquettes from sawdust. I performed research to inform the prototype design and created the prototype using SolidWorks and fabrication techniques such as 3D printing and sheet metal. I also produced, edited, and provided the voice-over for a video summarizing the project.

Infinity Club

I founded and am serving as president of a university student organization at Colorado School of Mines. Infinity Club is a neurodivergent affinity club that focuses on community building, advocacy, and connecting members to the broader neurodiversity community and potential employers. I work with a leadership team to plan social events and advocacy campaigns for over 50 members. I have given presentations and led workshops to improve visibility of neurodivergent students and encourage a more neuro-inclusive campus culture.

Contact

Interested in my work or have any questions? Feel free to reach me via email.